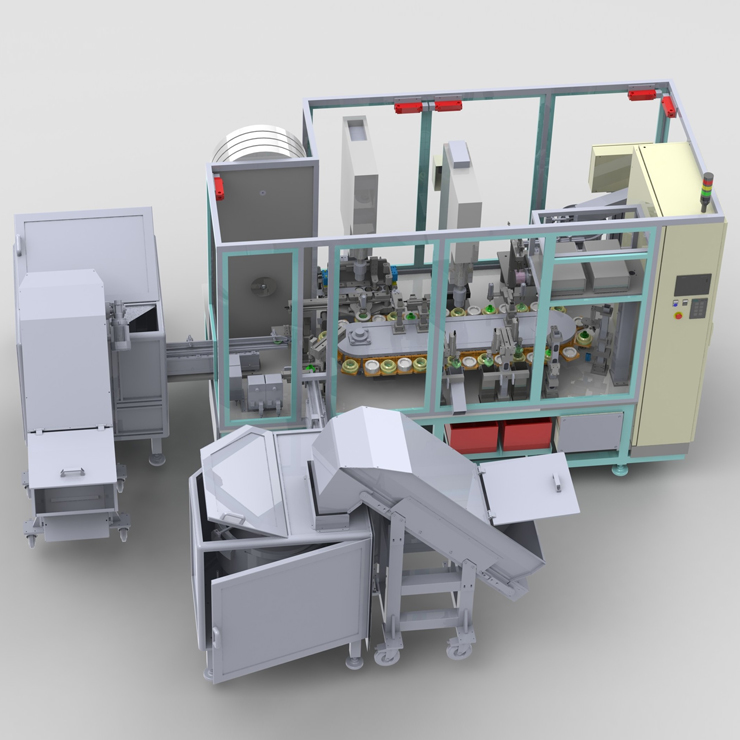

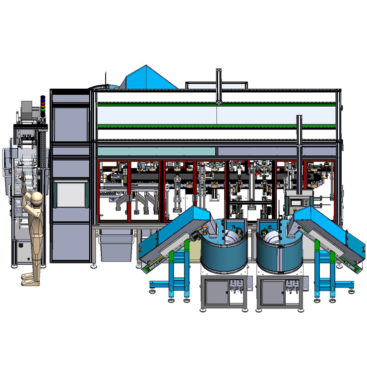

Automation for production of breathing filters.

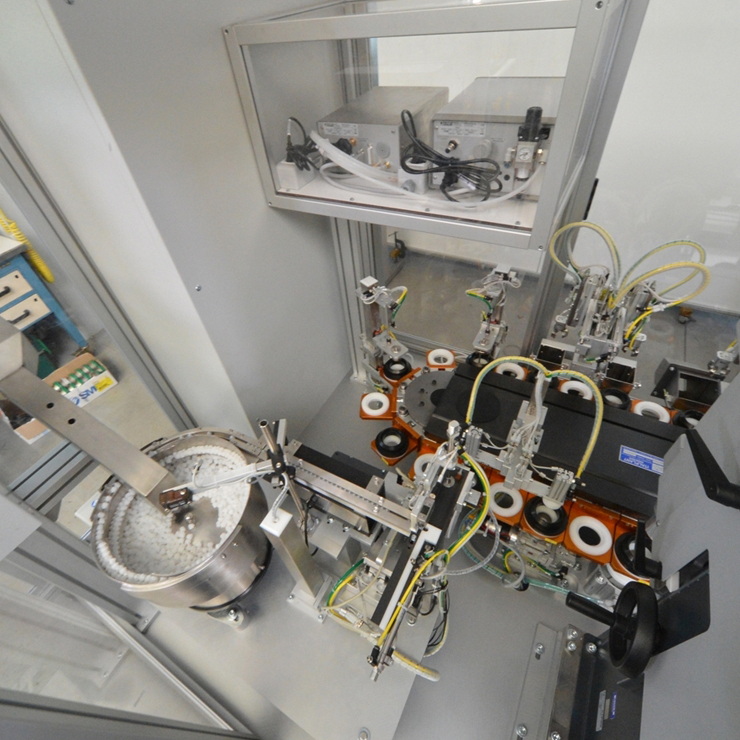

- Automatic loading of components (Lid, Bottom and Luer Cap).

- US cutting of the filtering membrane and automatic insertion into bottom, with unwinding system and waste recovery.

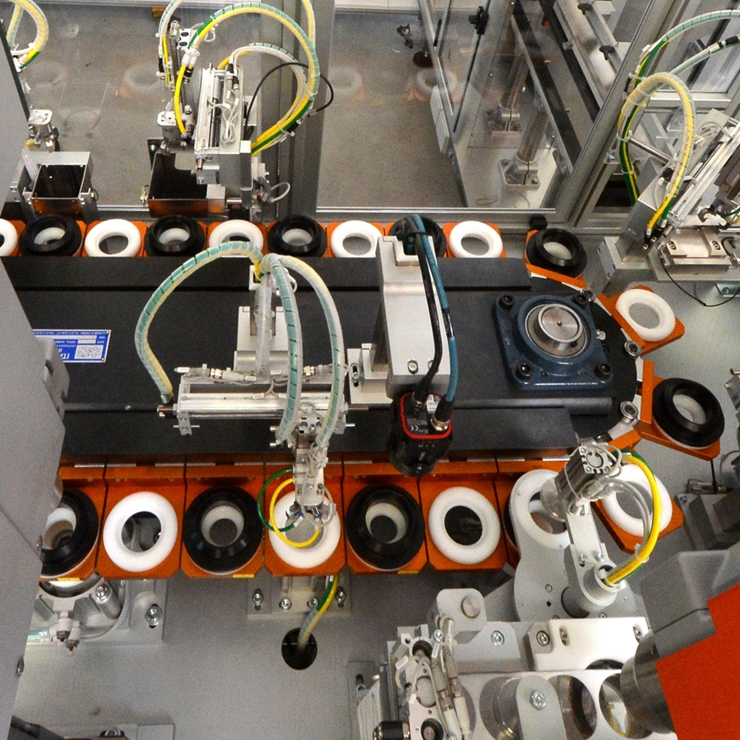

- Automatic assembly of the lid and the bottom by ultrasonic welding.

- Automatic positioning and screwing of the Luer cap on the cone.

- Automatic leak and flow testing.

- Automatic discharge of good parts.

- Automatic unloading of the rejected parts distinguished between sealing waste and generic waste.

Productivity: 840 pieces / h (according to customer requirements).